You are viewing the article Cast-in-Place Concrete Anchors – Williams Form Engineering Corp. at Tnhelearning.edu.vn you can quickly access the necessary information in the table of contents of the article below.

Cast-in-Place Concrete Anchors

Williams Form Engineering can supply a wide range of cast-in-place concrete anchor systems. Ranging from J-Bolts, and L-Bolts to a special post-tensionable anchor system that Williams has used on several high profile projects. Anchor design criteria for cast-in-place anchors can be found in ACI 318.

Cast-in-Place Post-Tensionable System

The system shown below allows the engineer to design an anchor system that can be cast-in-place and after the concrete sets, the anchor can be prestressed. The bond breaker provides a free stress length commonly used in post-tensioning systems. The free stress length helps to prevent load loss and concrete spalling that can eventually lead to corrosion problems or fatigue failure. After the anchor is prestressed, the inside of the sleeve can be grouted or it can be pre-greased with a corrosion inhibiting product prior to anchor placement.

Stress Gradient Pigtail Anchor

Williams patented Stress Gradient Pigtail Anchor has a unique design, which gradually increases the depth of each crimp to develop a full length Pigtail anchor. The lesser crimps in front allow the Pigtail to elongate through the concrete thereby transferring stress over its entire length. The stress gradient anchor is a positive “non-slip” anchor, which maybe placed within 3” of an edge even in low compression strength concrete.

Williams combines the extra strength of stress gradient Pigtail anchors with high tensile 120 KSI steel for more strength per pound than mild steel. A 1/2” high tensile bar will do the work of a 5/8” mild steel bar. Always remember the anchors should be set during pour and no later than one hour after completion of the pour. Work concrete well around Pigtail when placing.

When using WilliamsStress Gradient Pigtail Anchors, the following factual advantages are accomplished.

- Maximum embedment of the Pigtail Anchor is achieved

- The stress gradient crimp pattern deforms the steel for excellent bonding strength

- The high tensile steel offers high working loads with no welds which can limit strength

B5S Stress Gradient Pigtail Anchor – ASTM A108 Grade C1045

| Standard Lengths | Radiused Lengths | Safe

Working Load (2:1 SF) |

Ultimate

Strength |

|||

| Diameter | Total

Length |

A | B | C

Total Length |

||

| 3/8” – 8 NC

(9.5 mm) |

12”

(305 mm) |

4”

(102 mm) |

10”

(254 mm) |

22”

(559 mm) |

4.9 kips

(22 kN) |

9.8 kips

(44 kN) |

| 1/2” – 13 UNC

(13 mm) |

18”

(457 mm) |

4”

(102 mm) |

10”

(254 mm) |

24”

(610 mm) |

8.5 kips

(38 kN) |

17 kips

(76 kN) |

| 5/8” – 11 UNC

(16 mm) |

24”

(610 mm) |

6”

(152 mm) |

12”

(305 mm) |

30”

(762 mm) |

14 kips

(60 kN) |

27 kips

(120.6 kN) |

| 3/4” – 10 UNC

(19 mm) |

24”

(610 mm) |

6”

(152 mm) |

12”

(305 mm) |

30”

(762 mm) |

20 kips

(89 kN) |

40 kips

(178 kN) |

| 7/8” – 9 UNC

(22 mm) |

30”

(762 mm) |

8”

(203 mm) |

14”

(356 mm) |

36”

(914 mm) |

28 kips

(123 kN) |

55 kips

(246 kN) |

| 1” – 8 UNC

(25 mm) |

36”

(914 mm) |

8”

(203 mm) |

14”

(356 mm) |

42”

(1067 mm) |

36 kips

(162 kN) |

73 kips

(323 kN) |

| 1-1/8” – 7 UNC

(29 mm) |

36”

(914 mm) |

N.A. | N.A. | N.A. | 41 kips

(180 kN) |

81 kips

(360 kN) |

| 1-1/4” – 7 UNC

(32 mm) |

42”

(1067 mm) |

N.A. | N.A. | N.A. | 51 kips

(254 kN) |

102 kips

(508 kN) |

| 2” – 6 UN

(51 mm) |

72”

(1829 mm) |

N.A. | N.A. | N.A. | 139 kips

(657 kN) |

279 kips

(1313 kN) |

Anchor data reflects results from in house testing and the cast-in-place anchors do not conform to the code requirement of ACI 318. Pigtail lengths shown are recommended for 3000 PSI concrete or better.

B3Z Column Anchor

Williams B3Z Column Anchor was designed for use in most general construction, specifically machine, column or utility pole anchoring. The two-piece feature gives this anchor the ability to be placed flush with the concrete, therefore, eliminating interference during concrete placement and finishing. The anchor stud can then be conveniently threaded into the replaced anchor assembly as needed. Williams Column Anchor studs and bars are fabricated from ASTM A108 Grade C1045 steel with a high tensile strength. Couplings are designed to exceed bar strengths. Anchors are available in most diameters. Plastic caps are provided to protect the threads during concrete pouring

B4S J-Bolts

Round or square bottom J-bolts with most length and radius combinations available for a wide range of applications. Available in most diameters with coil or V-thread. To order, please specify diameter, A and B dimensions, thread type and length.

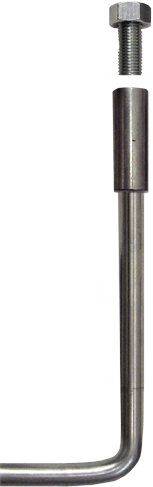

B3S L-Bolts

May be used as embedded anchor bolts. Available in most diameters with coil or V-thread. To order, please specify diameter, A and B dimensions, thread type and length.

Thank you for reading this post Cast-in-Place Concrete Anchors – Williams Form Engineering Corp. at Tnhelearning.edu.vn You can comment, see more related articles below and hope to help you with interesting information.

Related Search: